Alright, peeps! So you wanna get that perfect spindle for your cnc router? No worries, I got you covered. Picking the right spindle isn’t just about grabbing the first one you see. It’s all about knowing your stuff, staying cool, and making smart choices. Let’s dive into the world of spindles and get you geared up like a pro!

Know Your Stuff CNC Router

First things first, you gotta get educated. Spindles aren’t rocket science, but you need to know the basics. We’re talking about RPM, power, and all those little details that make a big difference. Don’t sleep on this step, ’cause if you don’t understand what you’re buying, you’ll end up with something totally whack. So, hit up some tutorials, watch a few vids, and get the lowdown.

Watt’s Up?

- Determine the power rating needed for your projects.

- Choose higher wattage for heavy-duty work.

- Ensure the power supply is compatible with your setup.

Next up, it’s all about tech talk. Terms like torque, bearings, and collets might sound like jargon, but they’re super important. Torque is all about the twisty power, bearings keep everything smooth, and collets hold your bits tight. Get familiar with these terms so you can sound like a boss when you’re shopping around. It’s like learning a new language, but way cooler.

Finally, do a specs check. Compare the different spindle specs to see what fits your needs. Look at the power ratings, RPM ranges, and other features. This isn’t just a boring chore; it’s your chance to see what’s out there and what’s gonna make your cnc router sing. Check out user reviews and spec sheets to get a clear picture. Trust me, doing your homework here pays off big time.

Power Up CNC Router

Alright, let’s talk power. Watt’s up with all those numbers? The power rating is crucial ’cause it tells you how much juice the spindle’s packing. If you’re just doing light work, you don’t need a beast, but if you’re in it for the heavy-duty stuff, go big or go home. Higher wattage means more power, and more power means smoother, faster cuts. Don’t skimp on this if you want pro-level results.

High Speed

- Check the RPM range required for different materials.

- Select a spindle with an appropriate speed range.

- Ensure you can adjust the RPM for versatility.

High speed, baby! RPM (rotations per minute) is what you need to pay attention to next. Different materials need different speeds, so knowing your RPM range is key. Some spindles are like sports cars, super fast and smooth. Others are more like trucks, slow but powerful. Pick the one that matches your material and style. Too slow, and you’ll be grinding forever; too fast, and things might get messy.

Lastly, think heavy-duty. If you’re planning to put your spindle through some serious work, make sure it can handle the load. Cheap spindles might be tempting, but they can burn out fast under pressure. Look for spindles that are built to last and can keep up with your projects. Heavy-duty means better performance and less downtime, so invest wisely.

Size Matters of CNC Router

Now let’s talk size. Fit check is a must. Your spindle has to fit your cnc router perfectly, no ifs, ands, or buts. Measure your cnc router and compare it to the spindle specs. It’s like buying clothes online – you don’t want something that’s too big or too small. The right fit ensures everything runs smoothly and you don’t end up with a wobbly setup.

Adapter Options

- Identify if an adapter is needed.

- Choose high-quality adapters for best performance.

- Ensure the adapter fits both the spindle and cnc router.

Measure twice, cut once. This old saying holds true when you’re picking a spindle. Double-check the spindle dimensions and make sure they’re compatible with your cnc router. If the sizes don’t match, you’re looking at a whole lot of hassle. Get out that measuring tape and get precise. This step might seem boring, but it’s crucial for a perfect setup.

Adapter options can save the day if things don’t line up perfectly. Sometimes, you’ll find a spindle that’s almost perfect but needs a little help to fit your cnc router. That’s where adapters come in. They can bridge the gap and make everything work together. Just make sure the adapter is high-quality and won’t mess up the performance. Problem solved!

Cool Factor of CNC Router

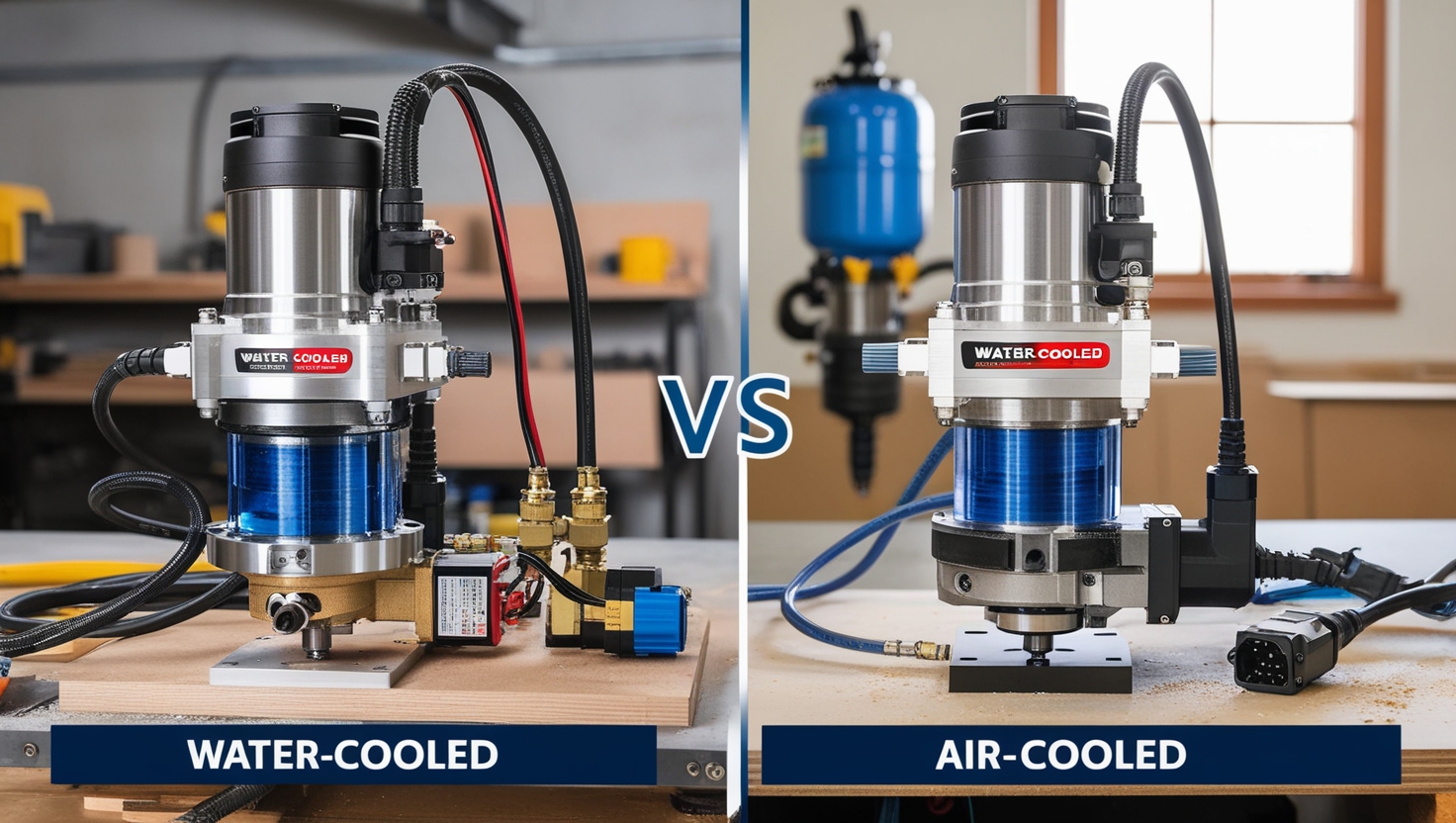

Stay chill, my friends. When it comes to spindles, cooling is a big deal. Water-cooled vs air-cooled – what’s the scoop? Water-cooled spindles are like that cool drink on a hot day. They keep things from overheating, especially during long, intense sessions. They’re great if you’re a heavy user who pushes your equipment to the max.

H2O Efficiency

- Opt for water-cooled spindles for heavy, continuous work.

- Prepare for additional setup and maintenance.

- Ensure efficient water cooling to avoid overheating.

H2O efficiency is where water-cooled spindles shine. They’re perfect for heavy, continuous use because they keep the temperature down and performance up. But remember, they need a bit more setup with water lines and maintenance. It’s like having a high-maintenance friend – worth it if you’re in it for the long haul.

Air power is simpler and easier to set up. Air-cooled spindles are more like your everyday heroes. They might not handle extreme conditions as well as water-cooled ones, but they’re easy to install and maintain. No extra water lines, just plug and play. If you’re a casual user or just starting out, air-cooled might be your best bet.

Noise Control of CNC Router

Sound off! Noise level is something you definitely want to consider. Some spindles are as loud as a rock concert, while others purr like a kitten. If you’re working in a shared space or just value your peace and quiet, look for a spindle that doesn’t sound like a jet engine taking off. Your ears will thank you, and so will your neighbors.

Ear Savers

- Look into additional cooling to reduce noise.

- Use soundproofing materials if necessary.

- Wear ear protection during operation.

Silent running is the dream. Low-noise spindles are out there, and they can make a huge difference in your working environment. It’s not just about comfort; less noise means you can focus better and work longer without getting annoyed. Quiet spindles might cost a bit more, but the peace of mind is worth every penny.

Ear savers are crucial if you’re stuck with a loud spindle. Look into extra cooling options to keep the noise down. Sometimes, adding better cooling can reduce the noise, or you might need to invest in some soundproofing gear. Don’t forget about ear protection either – good quality headphones can make a world of difference.

Budget Wisely of CNC Router

Money talks, folks. Know your budget and stick to it. It’s easy to get carried away with all the shiny options out there, but remember, you gotta eat too. Set a realistic budget and don’t stray too far from it. There are great spindles at every price point; you just need to find the one that fits your wallet and your needs.

Bang for Buck

- Look for spindles that offer great value.

- Compare prices and features to find the best deal.

- Prioritize reliability and performance.

Bang for buck is what you’re after. Look for spindles that offer the most value. Sometimes, a mid-range spindle can offer more reliability and features than a cheaper, no-name brand. It’s all about getting the best performance without breaking the bank. Read reviews, compare prices, and find that sweet spot where quality meets affordability.

Future proof your investment. Think about the long-term costs and potential upgrades. A cheap spindle might save you money now but could cost you more in repairs and replacements later. Spend a bit more upfront for a spindle that will last and can grow with your needs. It’s like buying a good pair of shoes – better to invest in quality than to keep replacing cheap ones.

Brand Hype of CNC Router

Brand trust is no joke. Go for reputable brands known for their quality and reliability. They’ve got the experience and the customer base to back up their claims. Sure, you might pay a bit more, but you’re also buying peace of mind. Stick with brands that have a good track record and positive reviews.

Review Roundup

- Read user reviews and ratings.

- Look for consistent feedback on performance.

- Avoid spindles with frequent negative reviews.

Support squad is essential. Make sure the brand you choose has good customer service and a solid warranty. If something goes wrong, you want to know that they’ve got your back. It’s not just about the product; it’s about the whole package. Check out the warranty terms and see what kind of support you can expect.

Review roundup is your best friend. Read up on what other users have to say. Real-world reviews can give you insights that specs alone can’t. Look for patterns in the feedback – if lots of people mention the same issues, take note. Reviews can help you dodge a bullet and find a spindle that truly delivers.

Installation Ease CNC Router

DIY ready is where it’s at. You don’t want to spend hours wrestling with your spindle, so look for one that’s user-friendly. Easy installation means you can get up and running faster. Check out the installation process before you buy and see if it’s something you can handle on your own or with minimal help.

| DIY Ready | Manual Matters | Tool Time | Additional Tips |

| Look for user-friendly spindles | Ensure the manual is clear | Check the kit for necessary tools | Plan the setup process |

| Verify easy installation | Detailed instructions matter | Have basic tools on hand | Watch tutorial videos |

| Avoid complex setups | Avoid poorly written manuals | Ensure you’re not missing tools | Prepare workspace beforehand |

Manual matters big time. Clear, detailed instructions can make or break your setup experience. A good manual will guide you through each step and help you avoid common pitfalls. Don’t underestimate the power of a well-written guide. It’s like having a buddy who’s done it before showing you the ropes.

Tool time means making sure you have everything you need for the install. Some spindles come with all the necessary tools, while others expect you to have your own. Check the kit contents and make sure you’re not missing any crucial pieces. Having the right tools on hand can make the installation process smooth and stress-free.

Future Upgrades CNC Router

Mod squad, rise up! Think about potential upgrades or expansions down the line. Maybe you want to add some fancy new features or enhance your setup. Choose a spindle that can grow with you. It’s all about keeping your options open and future-proofing your investment. A flexible spindle is a smart buy.

Compatibility check is key for future upgrades. Make sure any add-ons or expansions you’re considering will work with your spindle. There’s nothing worse than buying an upgrade only to find out it doesn’t fit. Do a bit of research and see what’s possible with the spindle you’re eyeing. Planning ahead can save you a lot of headaches.

Tech trends are always evolving, so stay updated with the latest spindle technology. New innovations can make your life easier and your projects better. Keep an eye on what’s new in the world of spindles and see if there’s something that catches your interest. Staying current means you can take advantage of new features and improvements as they come out.

And there you have it, folks! A spindle guide that’ll have you making the best choice like a true pro. Remember, it’s all about knowing your stuff, staying cool, and making smart choices. Get out there and pick the perfect spindle for your cnc router. Happy cutting!